Polycarbonate Sheets In All Forms

Best Polycarbonate Sheet You Could Find

Polycarbonate sheet is one of the most popular engineering plastics, which is virtually unbreakable and more than 250 times stronger than glass, but only half weight. It offers optical clarity, great fireproof performance, processability. Therefore, it is the ideal material to replace glass, acrylic, and tempered glass in wide applications. With the co-extruded UV layer on one or both sides, the polycarbonate sheet offers outstanding weatherability, it can keep clear for more than 10 years.

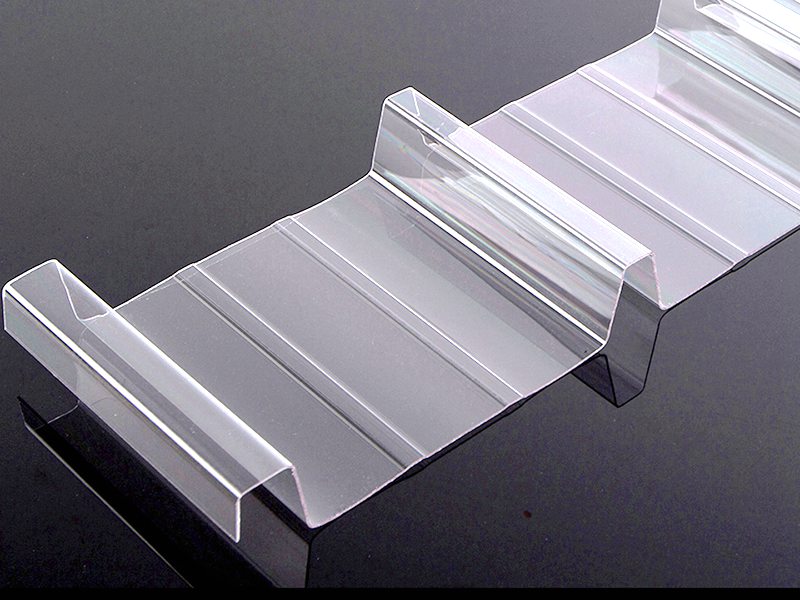

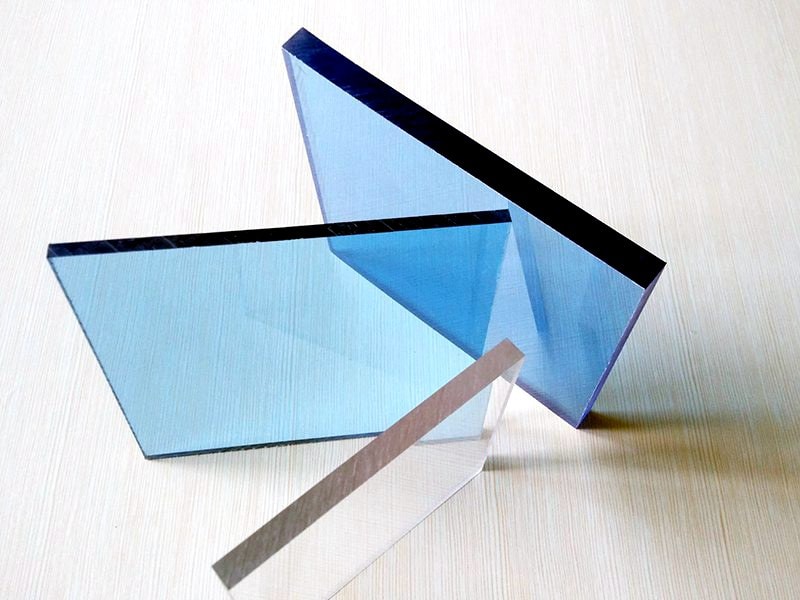

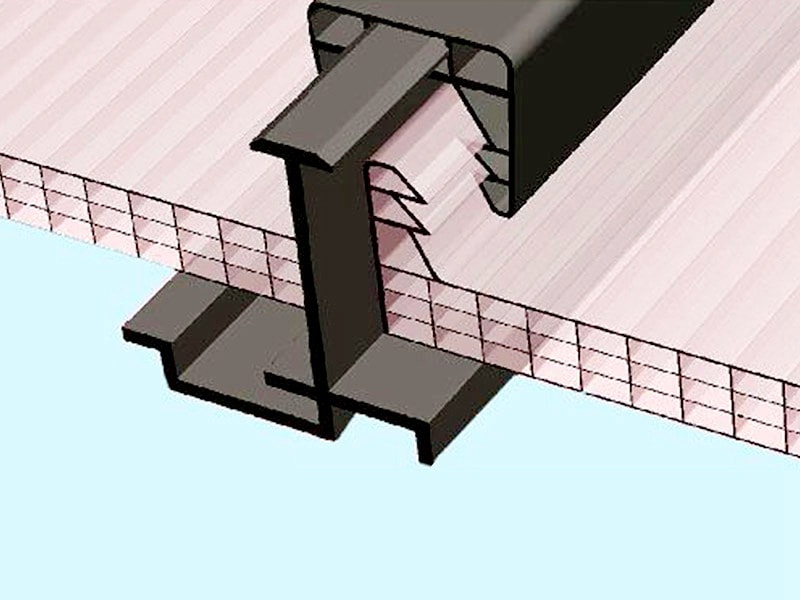

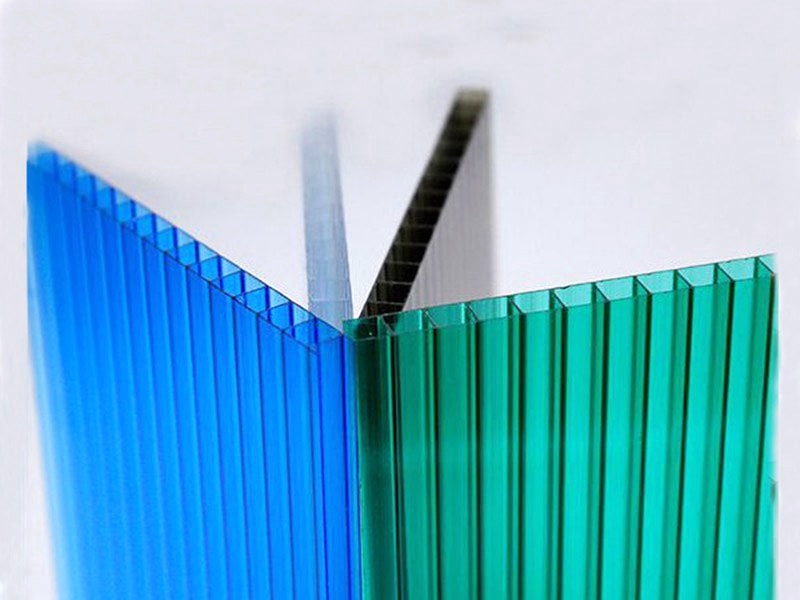

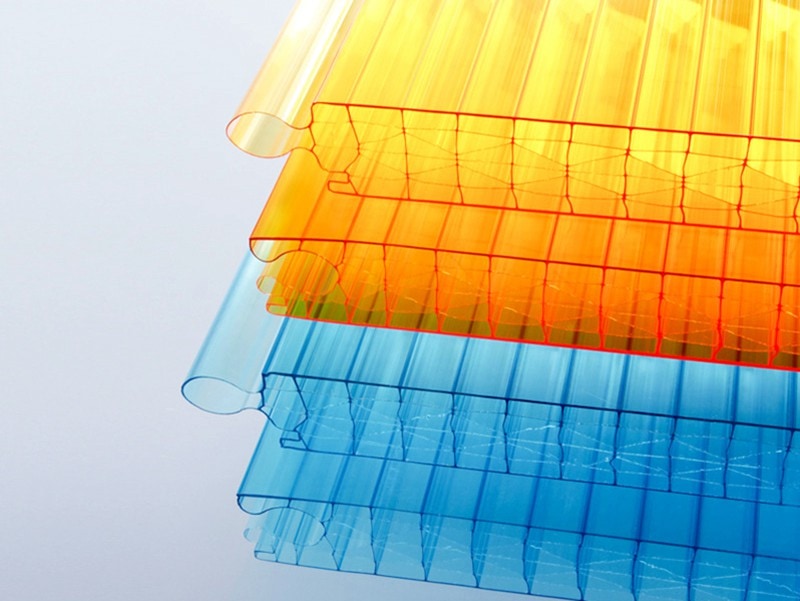

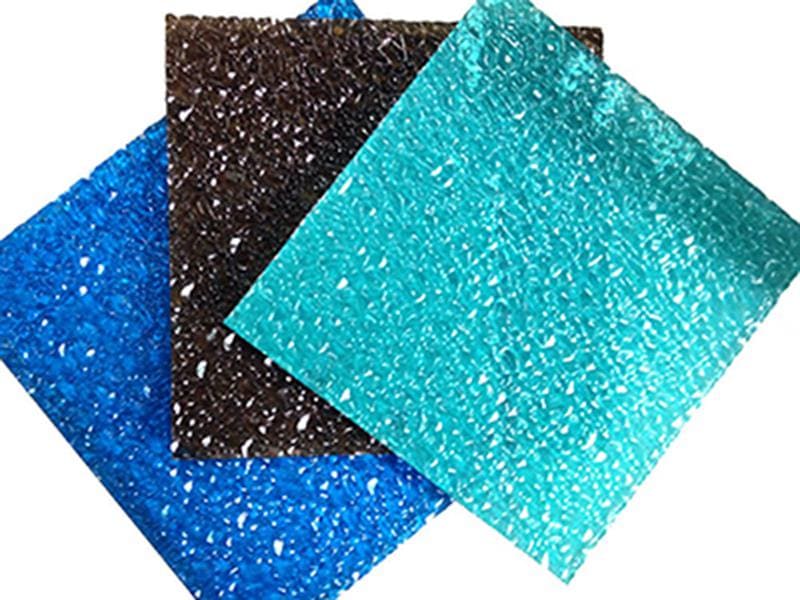

Polycarbonate sheets can be coated on one or both sides for the surface enhancements for some specific applications, for example, anti-static sheets, non-glare sheets. And also polycarbonate sheets can be manufactured for different structures, such as multi-layer, corrugated, plug-in types for architecture.

Providing Polycarbonate Sheets In All Forms

Since 1995, UVPLASTIC has been involved in the polycarbonate field as the provider of machining polycarbonate services in China. In 2003, we build our own factory to manufacture the high-quality polycarbonate sheet in Suzhou, China. With the continuous investment in manufacturing facilities and technology, we have grown to be a leading manufacturer of polycarbonate sheets in China.

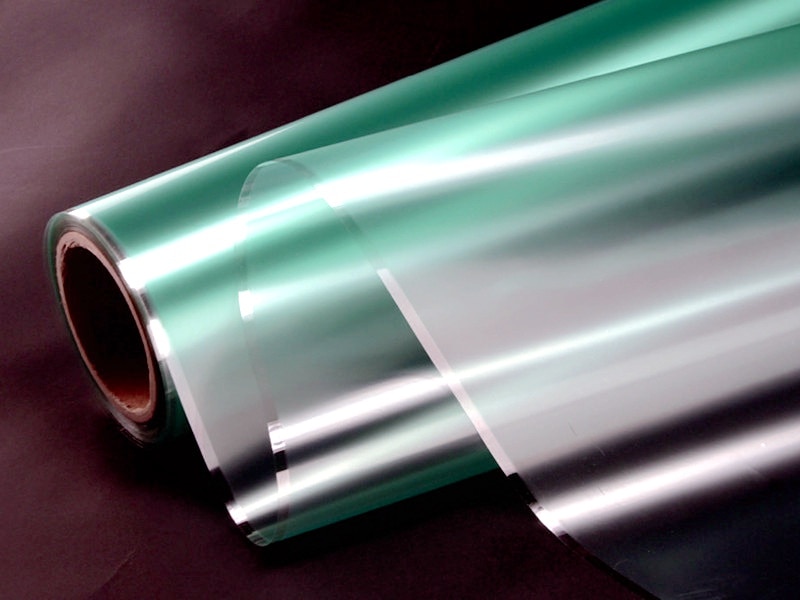

More than 17 years of experience and cooperation with the top suppliers of polycarbonate raw material, including Covestro/Bayer, Sabic, Mitsubishi, Teijin. UVPLASTIC manufactures high-quality polycarbonate sheets in all forms, including Flat Polycarbonate sheets, Multiwall Polycarbonate sheets, Thin Polycarbonate Sheets (Polycarbonate Film), Corrugated Polycarbonate Sheet, Polycarbonate Roofing Panel, Embossed Polycarbonate Sheet, and Polycarbonate Facade.

Meantime, UVPLASTIC provides polycarbonate sheets with a certain function by coating, such as anti-fog polycarbonate, anti-scratch polycarbonate, polycarbonate diffuser, fireproof polycarbonate, anti-static polycarbonate, etc.

With more than 25 years of experience in the field of polycarbonate plastic, we know more about polycarbonate sheets, machining polycarbonate, and trade rules between countries. Therefore, we are your best supplier of polycarbonate sheets in China. Today, we are so honored to cooperate with more than 2000 clients all over the world.

Specification Of UVPLASTIC™ Polycarbonate Sheets

UVPLASTIC™ polycarbonate sheets range

| No | Product Name | Model | Thickness Range | Max. Width | Coating Option |

|---|---|---|---|---|---|

| 1 | Flat Polycarbonate | UVFPC | From 1.5mm to 30mm | 2650mm | Extruded UV Layer, Anti Fog Layer, ESD Coating, Anti-scratch Coating, No-glare coating layer |

| 2 | Multiwall Polycarbonate | UVMPC | From 4mm to 50mm | 2100mm | Extruded UV Layer, Anti Fog Layer |

| 3 | Polycarbonate Film (thin polycarbonate sheet) | UVTPC | From 0.125mm to 1mm | 1220mm | Extruded UV Layer, Anti Fog Layer |

| 4 | Corrugated Polycarbonate | UVCPC | From 0.8mm to 2mm | 1220mm | Extruded UV Layer |

| 5 | Polycarbonate Roofing Panel | UVRPC | From 6mm to 50mm | 1040mm | Extruded UV Layer, Anti Fog Layer |

| 6 | Polycarbonate Facade | UVFA | 50mm | 500mm | Extruded UV Layer, Anti Fog Layer, Different Color-Layers |

Remark:

Available colors of tinted polycarbonate sheet

| Type | Color Description | Surface |

|---|---|---|

| Transparent | Clear, Bronze, Red, Blue, Green, Solar Grey, LighterBlue, Lighter Green | Smooth, Frosted, Embossed |

| Translucent | White Opal, White Diffuser, Yellow, Red, Mint Green, White Opal | Smooth, Frosted, Embossed |

| Opaque | Black, Yellow, Dark Blue, Cream, Dark Grey, Dark Brown | Smooth, Frosted, Embossed |

Remark:

UVPLASTIC can provide custom colors upon clients’ request, subject to a minimum order.

Coating service for polycarbonate sheets

For some applications, like snorkel mask, windshield, industrial clean room, face mask, etc, normal polycarbonate sheets can’t meet the requirements. Therefore, UVPLASTIC will coat the special layers on the one-side or two-side surface:

| No. | Coating Service | Description |

|---|---|---|

| 1 | Anti-static/ESD Coating | The surface resistance of polycarbonate from 10E5 to 10E8 Ohm, for industrial cleanroom, dust-free room. |

| 2 | Anti-fog Coating | Offers excellent anti-fogging properties and excellent anti-scratch performance. |

| 3 | Scratch Resistance Coating | Increase the surface hardness for 2-6 levels than the general-purpose polycarbonate sheets. |

| 4 | Non-glare Coating | Minimize glare and reflection with a matte finish, it creates a glare-free view from any angle. |

Physical Properties of polycarbonate sheets

For high-quality polycarbonate plastic sheets, UVPLASTIC always uses raw material from Sabic, Covestro/Bayer, here are the physical properties of Polycarbonate plastic.

| Property | Test Method | Testing Condition | Unit | Value |

|---|---|---|---|---|

| Density | D-792 | g/cm3 | 1.2 | |

| Heat Deflection Temperature | D-648 | Load: 1.82 MP | °C | 135 |

| Short Term Service Temperature | °C | from -50 to +130 | ||

| Long Term Service Temperature | °C | from -40 to +100 | ||

| Coefficient of Linear Thermal Expansion | D-696 | mm/m °C | 0.065 | |

| Thermal Conductivity | C-177 | W/m K | 0.21 | |

| Tensile Strength at Yield | D-638 | 10 mm/min | Mpa or N/mm² | >65 |

| Tensile Strength at Break | D-638 | 10 mm/min | MPa or N/mm² | >60 |

| Elongation at Yield | D-638 | 10 mm/min. | % | 6 |

| Elongation at Break | D-638 | % | >95 | |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | MPa | 2350 |

| Flexural Strength | D-790 | 1.3 mm/min. | MPa | 100 |

| Flexural Modulus | D-790 | 1.3 mm/min. | MPa | 2600 |

| Impact Falling Weight | ISO 6603/1 E50 | 3mm sheet | J | 158 |

| Light Transmission | D-1003 | % | 82 – 92 | |

| Haze | D-1003 | % | <0.5 | |

| Flammability rate | UL 94 | V-2 or V-0 |

Remark:

Default third-party testing organization is SGS;

Typic applications

Main Benefits of UVPLASTIC™ Polycarbonate Sheets

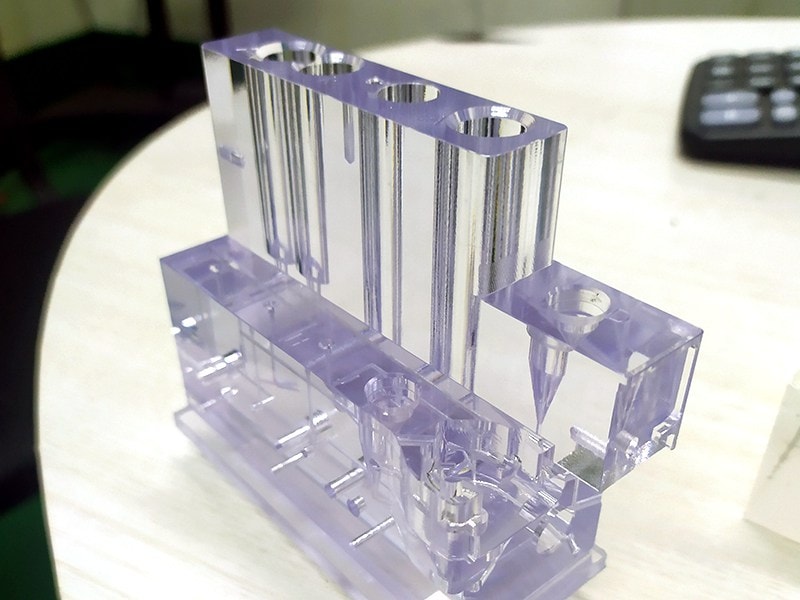

Machining Polycarbonate Sheets

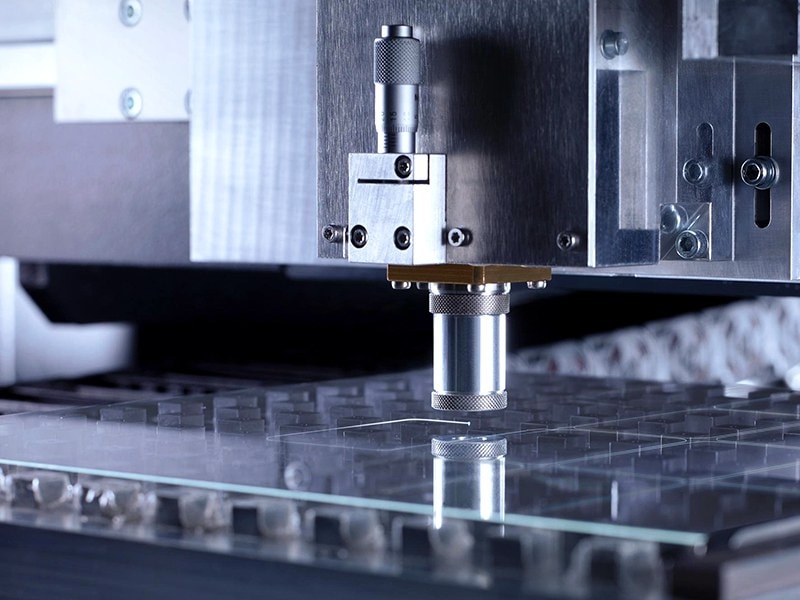

UVPLASTIC is a leading supplier of polycarbonate sheets and the provider of machining polycarbonate service.

With the sustained investment in manufacturing facilities, including cutting equipment, five-axis CNC machinery, thermoforming equipment, and printing equipment. Today, UVPLASTIC provides Integrated processing solutions including cutting to size, bending, CNC machining, finishing edge, polishing surface, thermoforming, and printing. The machining precision is ±0.01mm.