Best Machining Custom Polycarbonate Service

Best Machining Custom Polycarbonate Service Provider

Since 2003, UVPLASTIC has been involved in Machining Polycarbonate. With more than 17 years of experience and continuous investment in production equipment, we have grown to be the leading supplier of custom polycarbonate products in China. Today, we understand and provide the integrated machining method for your need for custom polycarbonate.

From Basic Polycarbonate Sheet To Finial Custom Polycarbonate

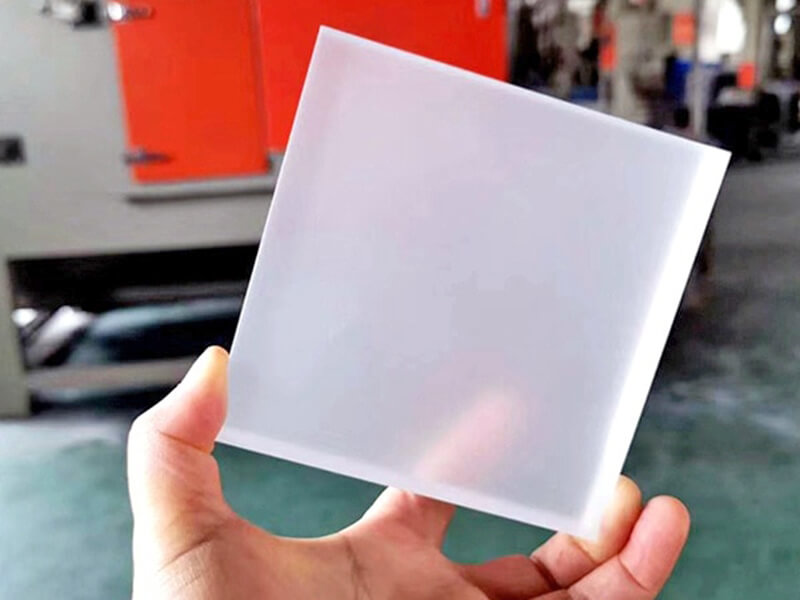

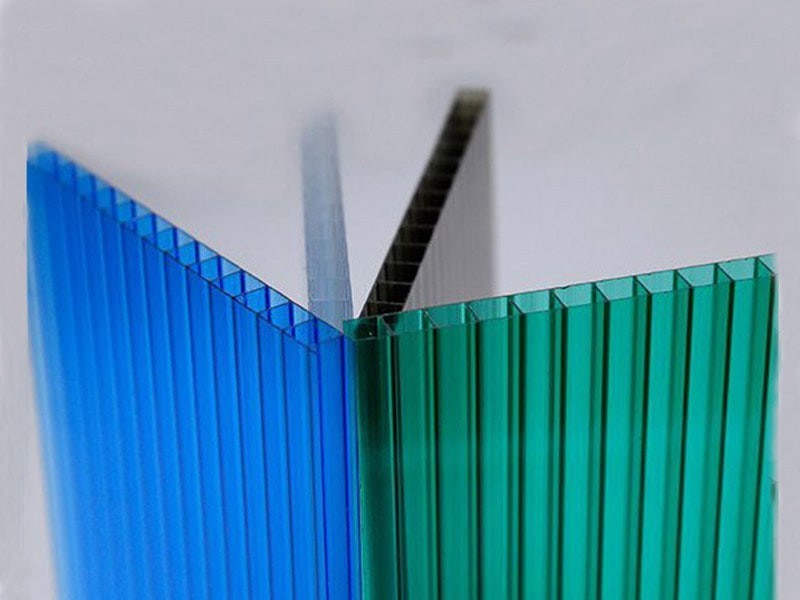

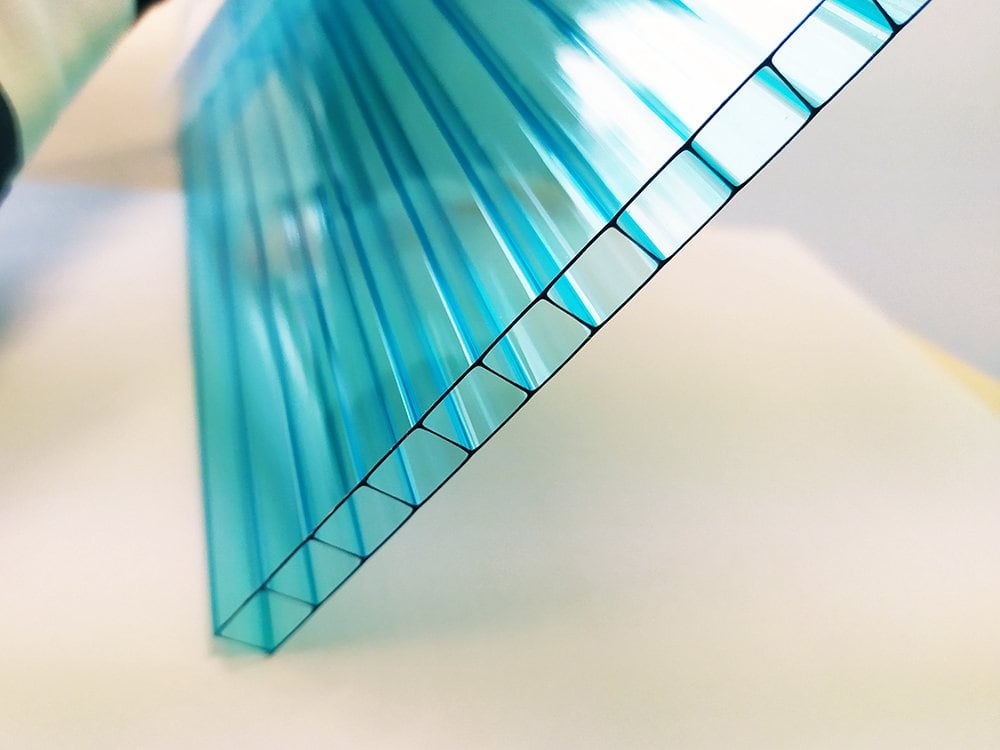

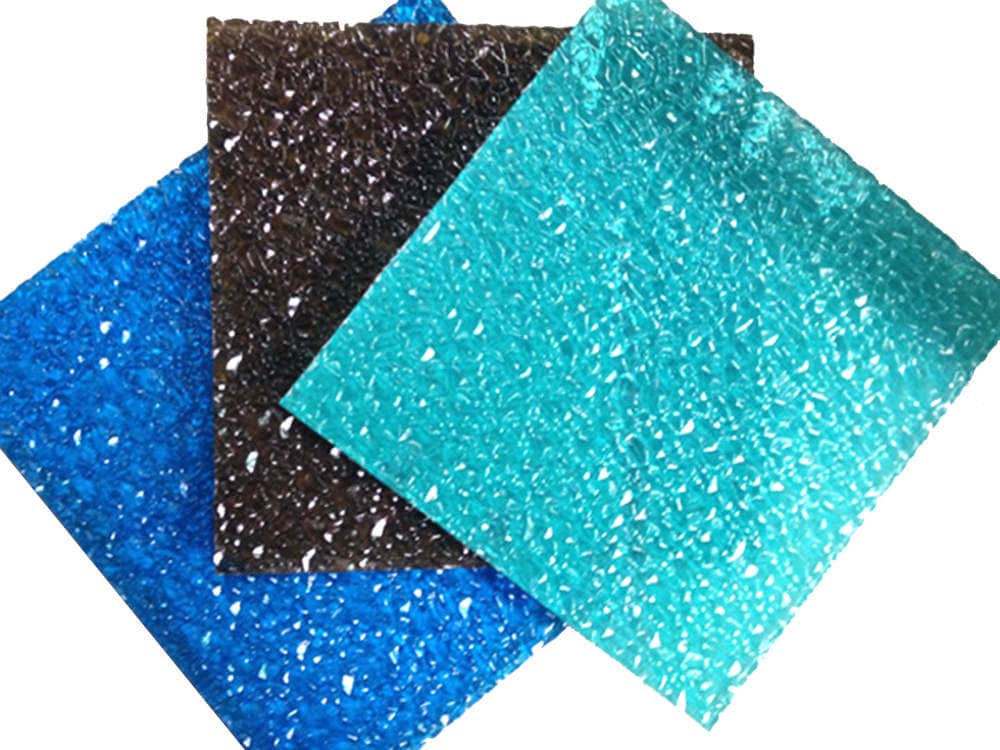

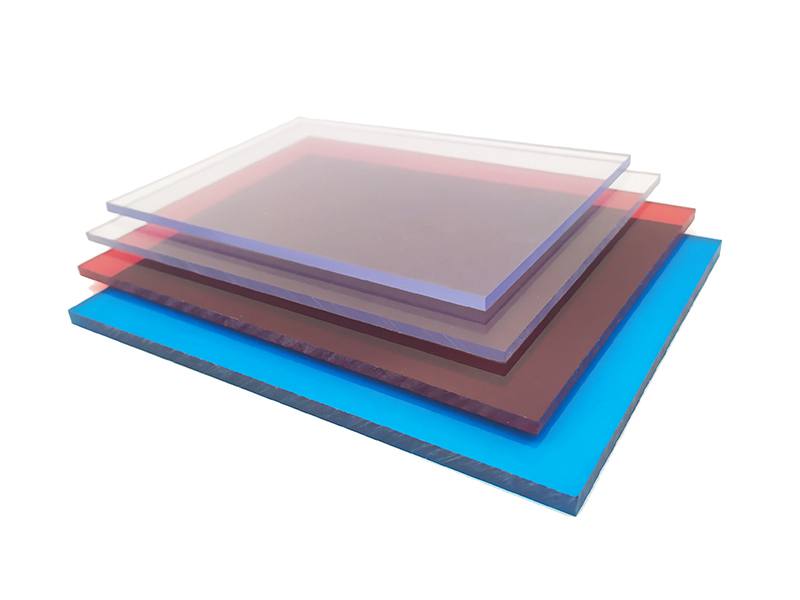

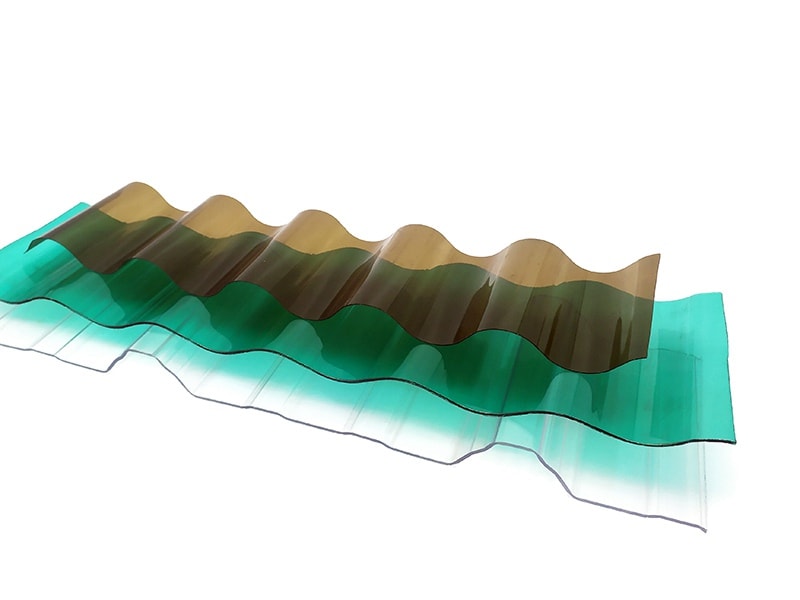

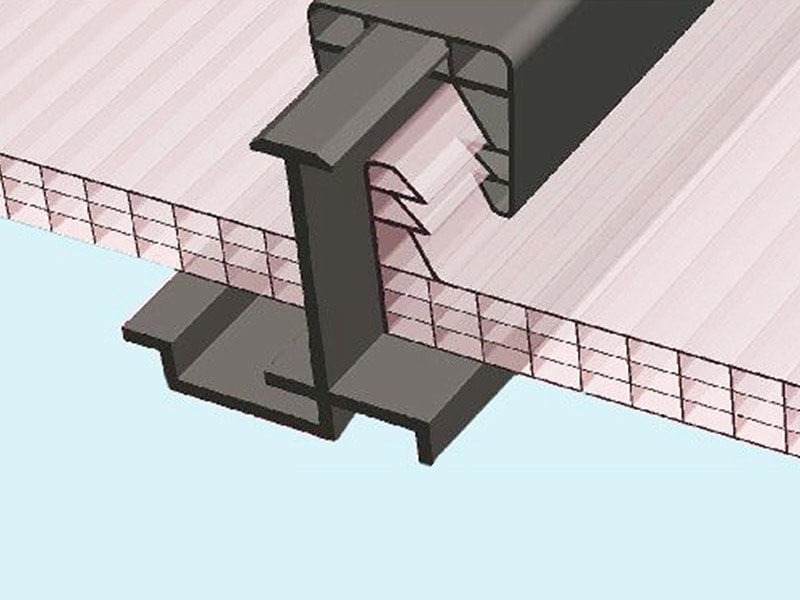

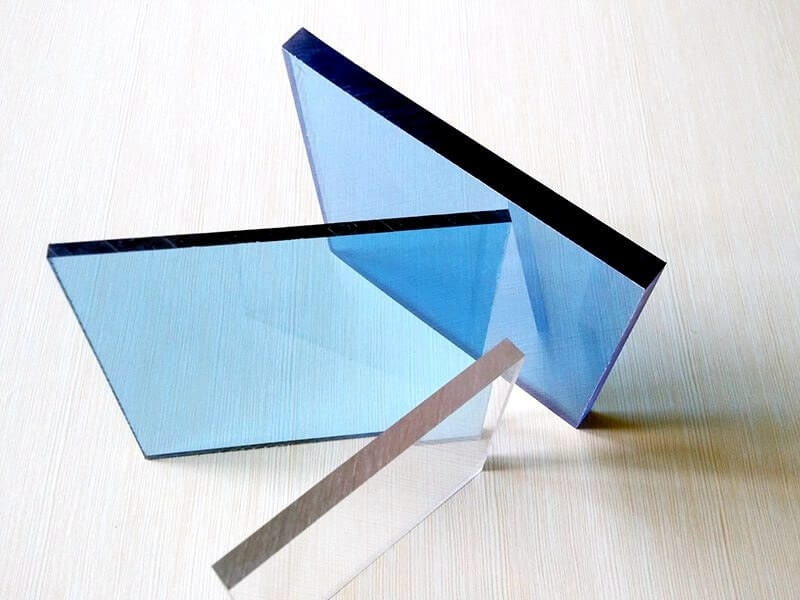

With the business growing, we built our own factory in 2007, and manufacture high-quality polycarbonate sheets by using raw materials from Sabic, Covestro/Bayer, MITSUBISHI, and TEIJIN. Therefore, we offer a competitive price and excellent leading time. By controlling the quality of the polycarbonate sheet, we provide high-quality custom polycarbonate to global clients.

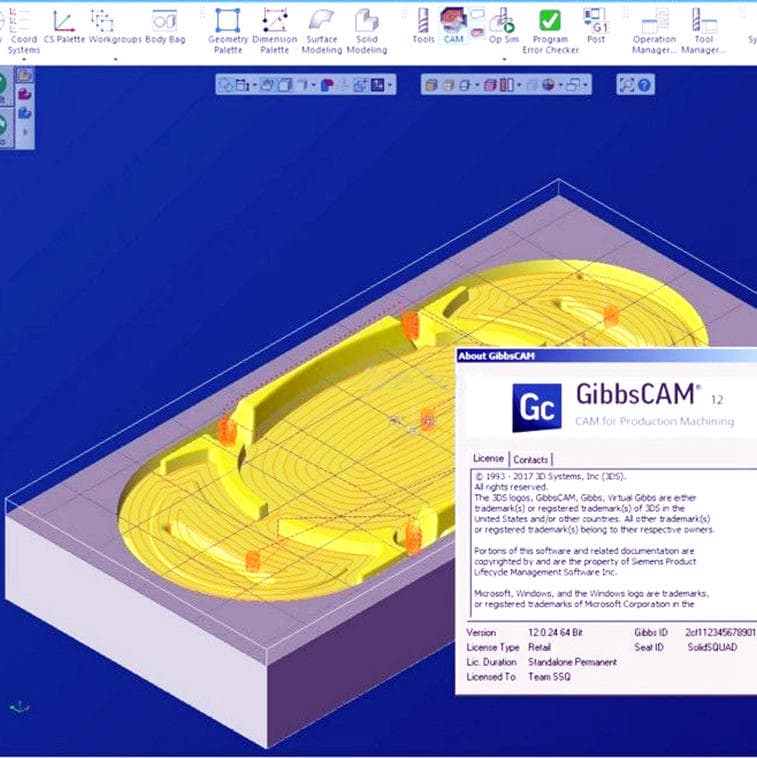

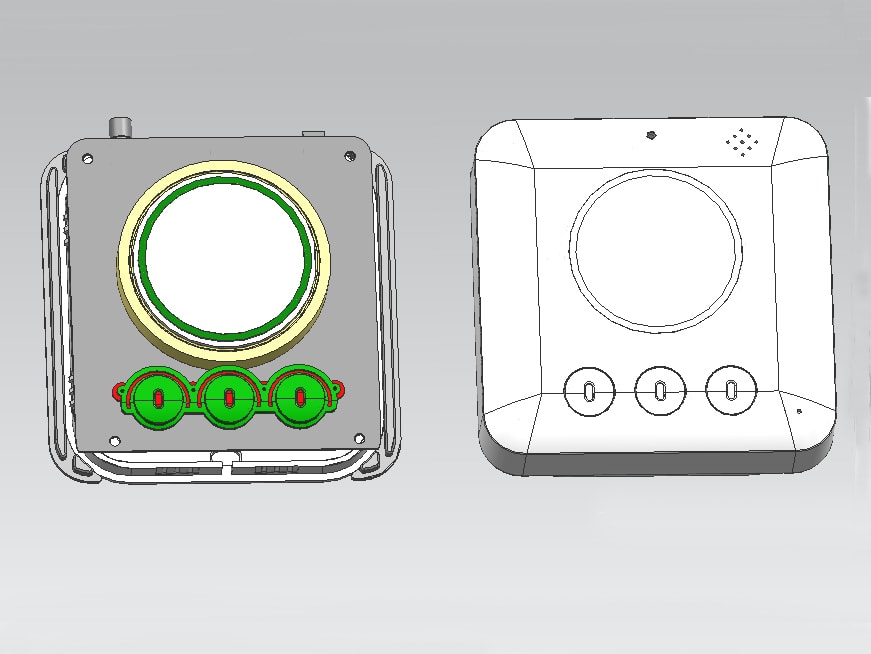

Designing Custom Polycarbonate And building the fast prototype

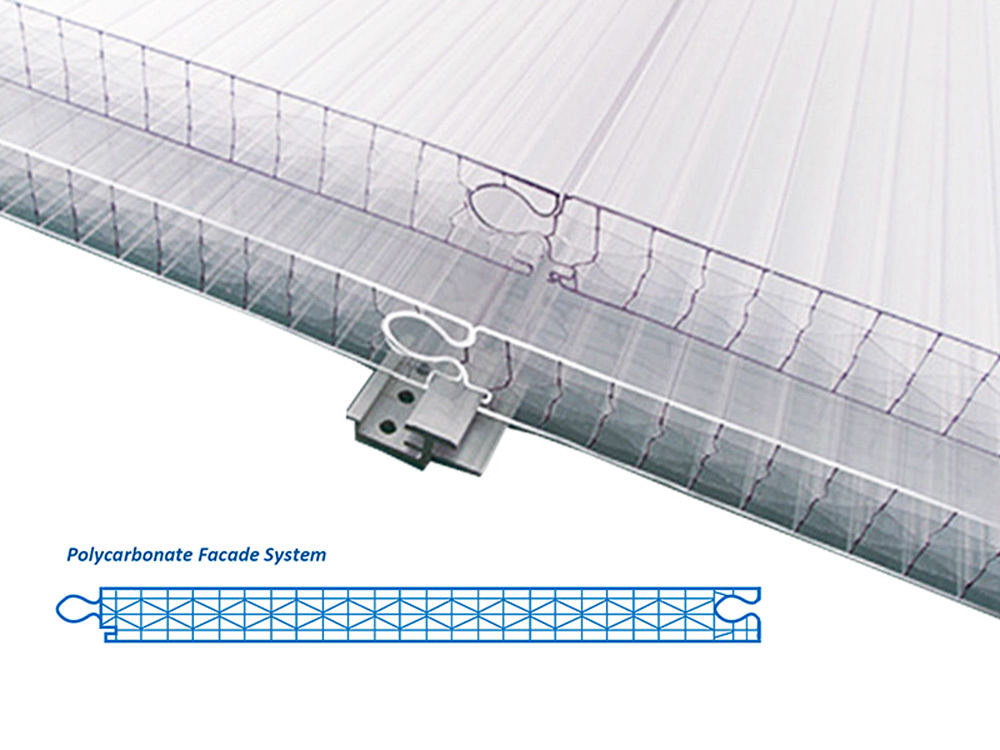

With the help of CAD, Solidworks, UG, CATIA, and CAM, our engineer designs the custom polycarbonate according to clients’ requirements, and always finds out the right solution with the highest cost-efficiency. Today, we are so honored to cooperate with more than 600 clients from more than 56 countries all over the world, they are active in architecture, medical industry, aircraft, packaging industry, automobile industry, tourism industry, sign&display, electric industry, decoration industry, etc.

Integrated Machining Polycarbonate Solutions

With more than 17 years of experience in the polycarbonate field, we have a better understanding of machining polycarbonate from designing to custom polycarbonate by the most cost-efficient machining solutions. Here are some machining methods for custom polycarbonate products.

Designing custom polycarbonate

With the help of CAD/CAM, Solidworks, CATIA, and UG, the engineers build 2D and 3D models on the computer at the beginning stage.

It helps engineers to find the most cost-efficient fabrication solution of custom polycarbonate for your coming project.

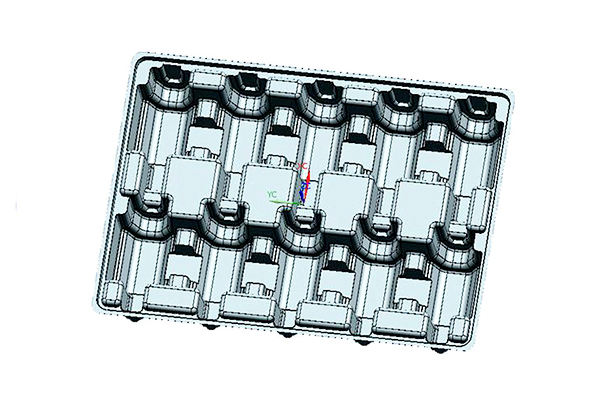

Fast Prototype

UVPLASTIC builds a wooden mold for production in small quantities. In this case, we can spend little money and time on prototypes.

It is also the best solution to manufacture custom polycarbonate parts as middle prototypes, like 200 pieces.

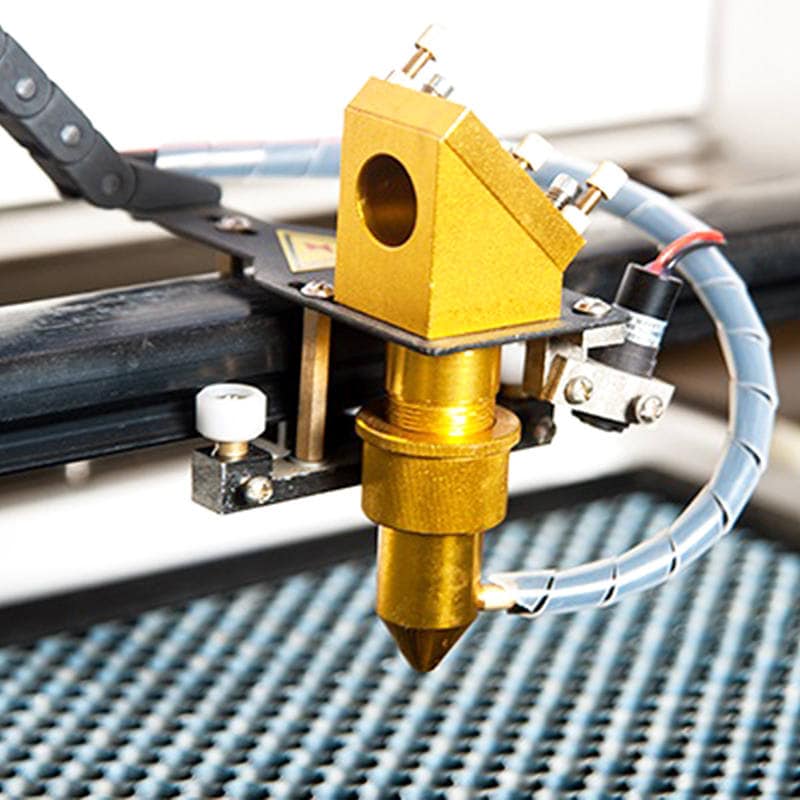

Cutting polycarbonate

UVPLASTIC offers different cutting solutions with high precision for not only polycarbonate sheet with 20mm thickness and polycarbonate film with 0.125mm thickness, but also a supersize polycarbonate panel.

| Items | Metric system | British system |

|---|---|---|

| Min. Thickness | 0.02mm | 0.001 inch |

| Max. Thickness | 25mm | 1 inch |

| Max. Length | 5m | 196 inches |

| Max. Width | 2.5m | 83 inches |

| Tolerance | ±0.05mm | ±0.002 inches |

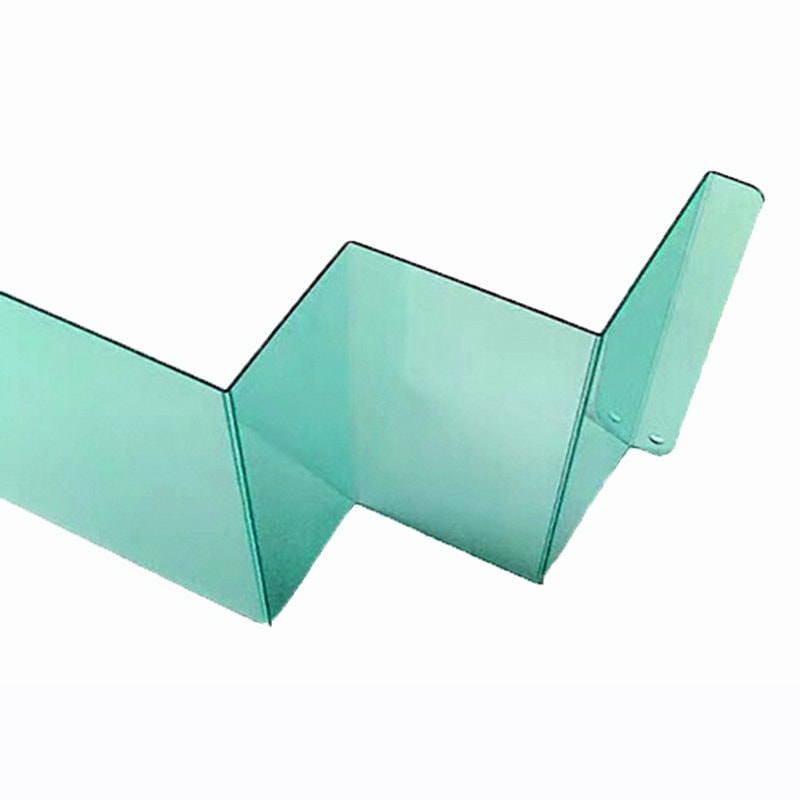

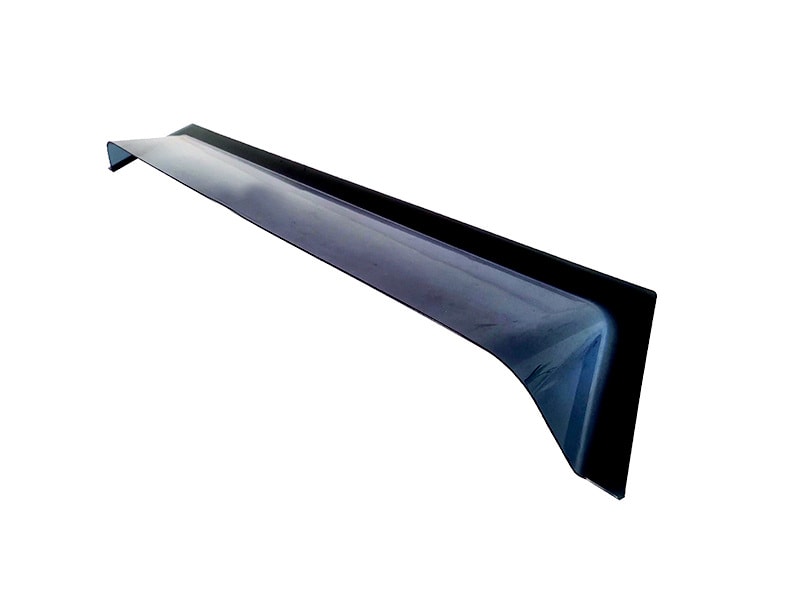

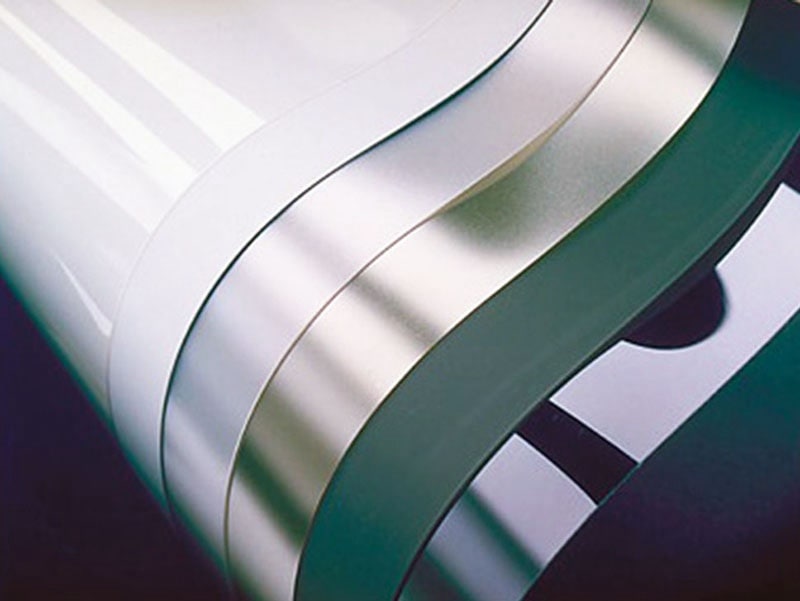

Bending Polycarbonate

UVPLASTIC provides the best bending polycarbonate solution with high precision, including cold bending, heat-bending, and V-groove Bending, just tell us the requirement of polycarbonate bending, our engineer will choose the right bending method;

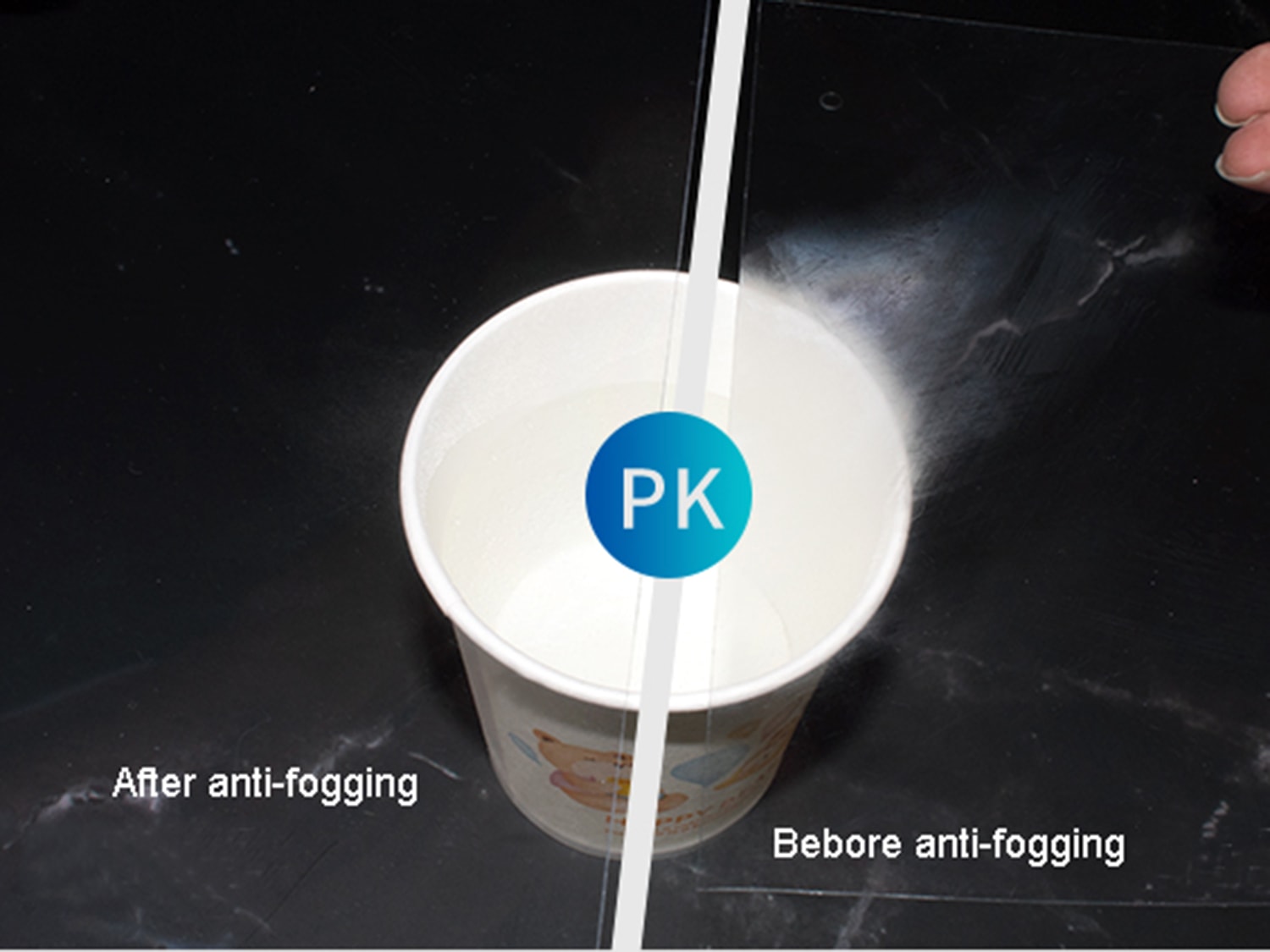

Coating Polycarbonate

UVPLASTIC provides a coating layer on the surface of solid polycarbonate sheet for the specific function and longer lifespan, including:

Finishing Edge

UVPLASTIC offers the perfect edge finishing solution for custom polycarbonate, which makes polycarbonate parts with safety and a great appearance including bevel edge, round edge.

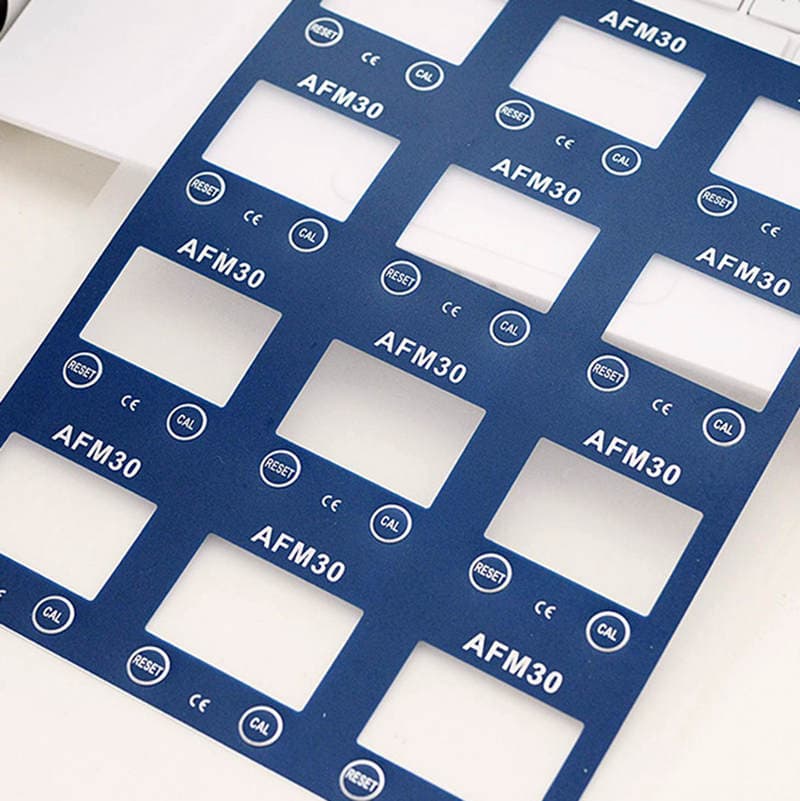

Printing Polycarbonate

UVPLASTIC offers excellent polycarbonate printing services including:

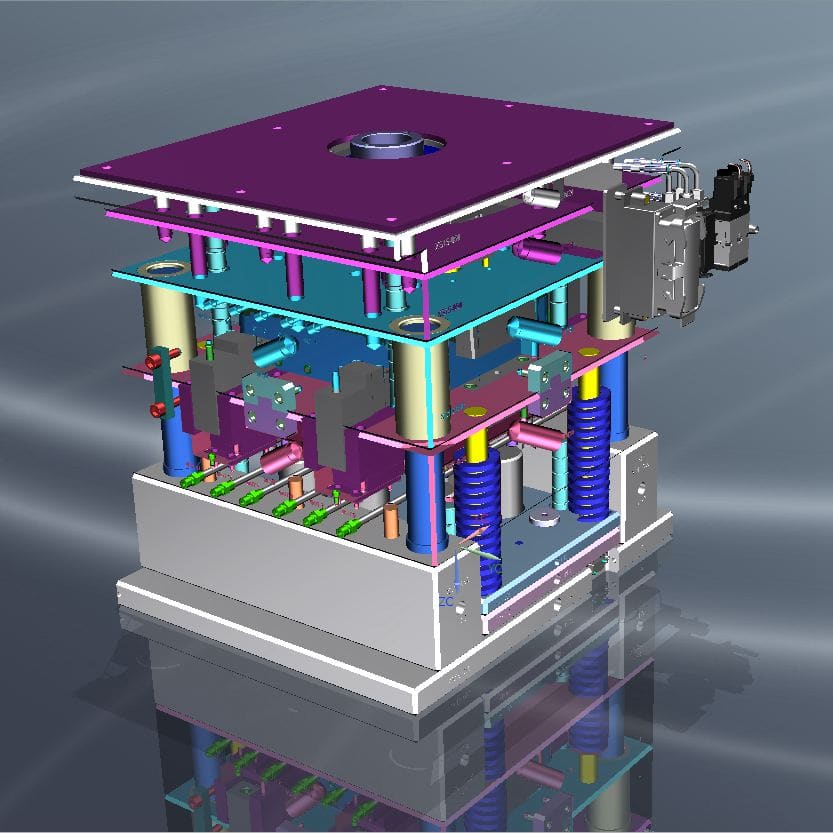

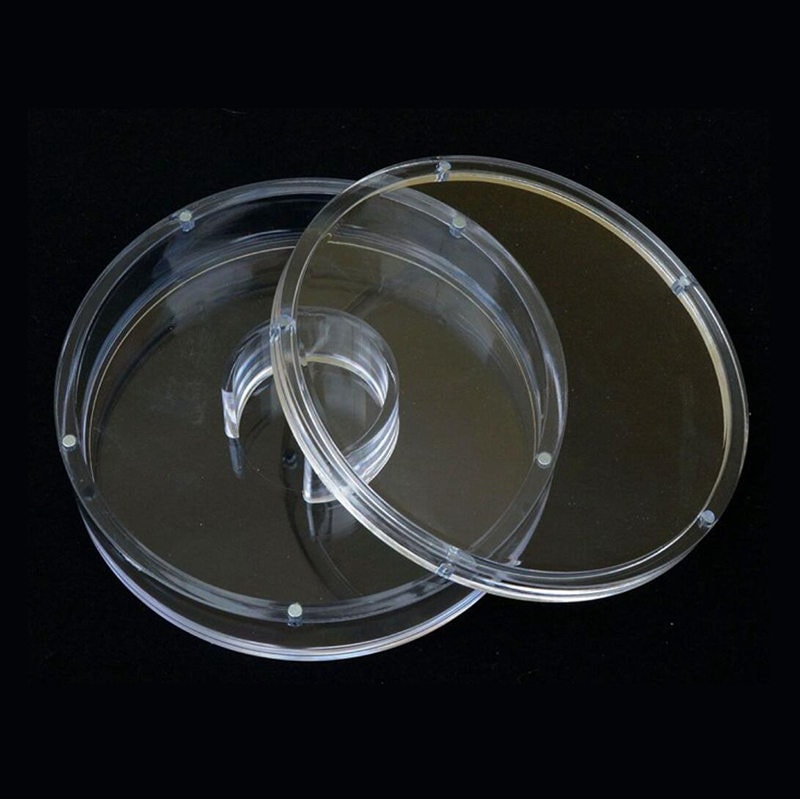

Injection molding custom polycarbonate

La solución de moldeo por inyección de policarbonato es l solution is the best solution for the small size of custom polycarbonate parts with big quantity. It offers high precision, complicated shape, great appearance. UVPLASTIC can offer you from designing injection mold to final custom polycarbonate parts.

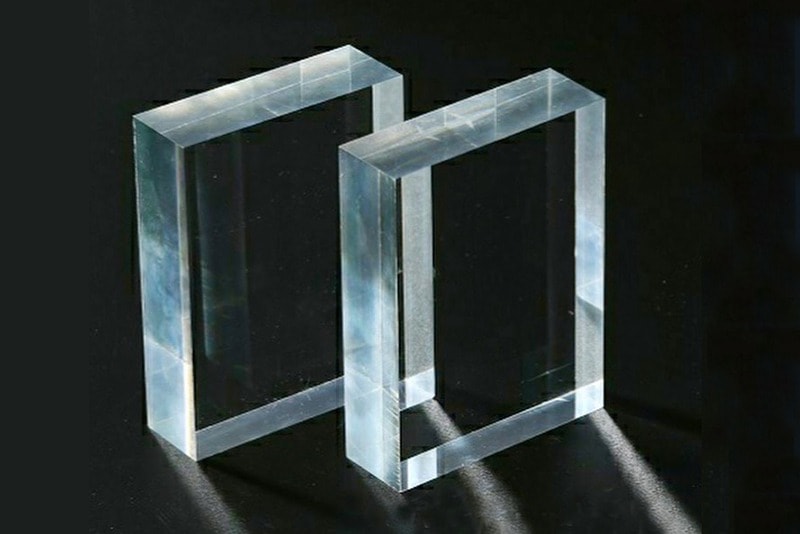

Polishing polycarbonate

UVPLASTIC offers excellent surface finishing solutions for eye-catching appearance, longer lifespan, such as:

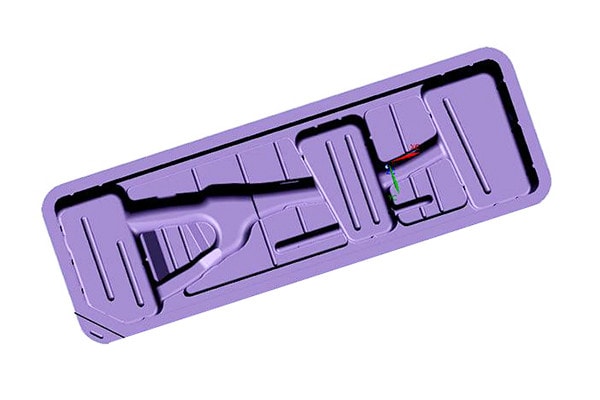

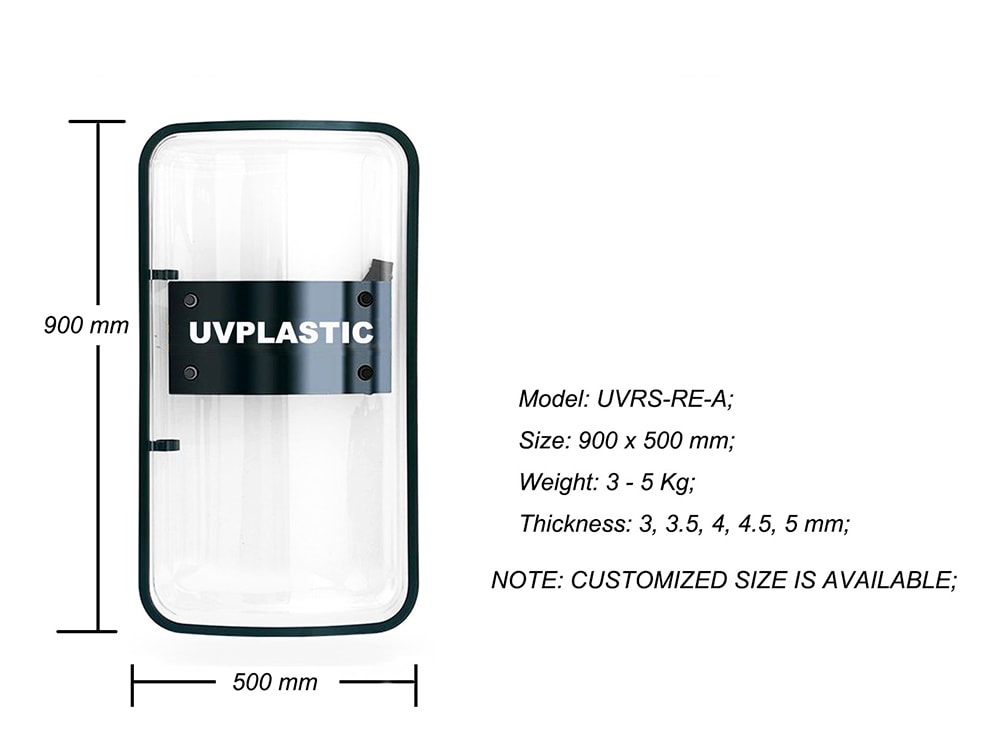

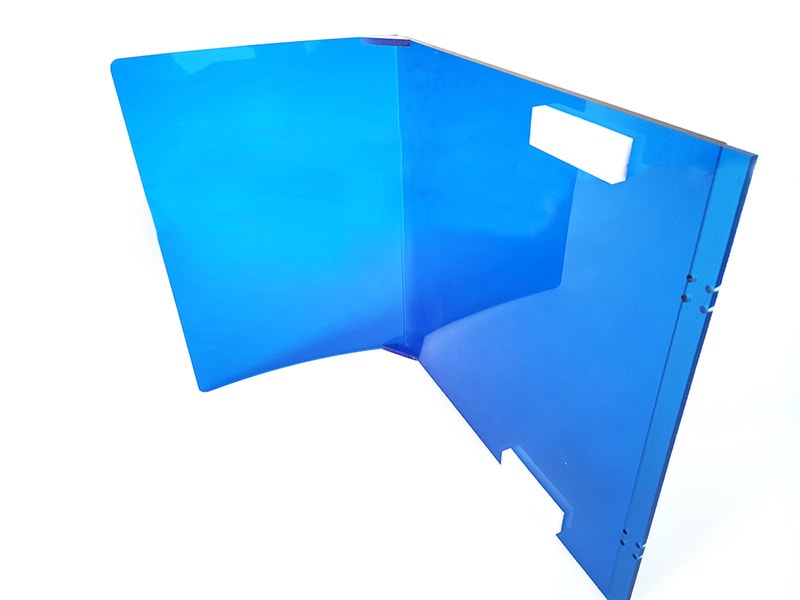

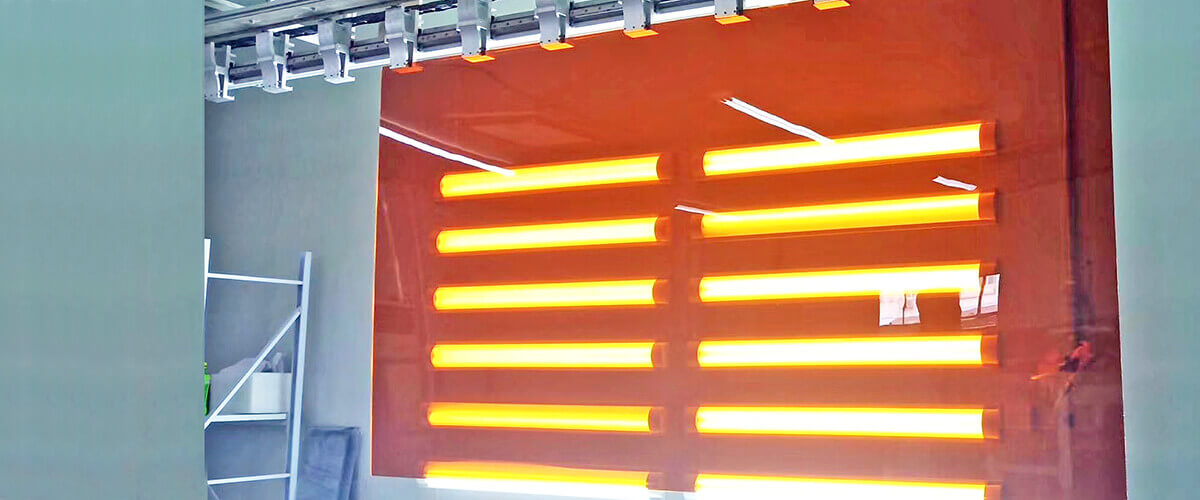

thermoforming polycarbonate

The thermoforming solution includes vacuum forming, compression molding, oven forming, it is the best solution for custom polycarbonate parts with small/middle quantities, for example, riot shield, clear kayak, bubble tent, polycarbonate tray, lampshade, polycarbonate suitcase, etc.

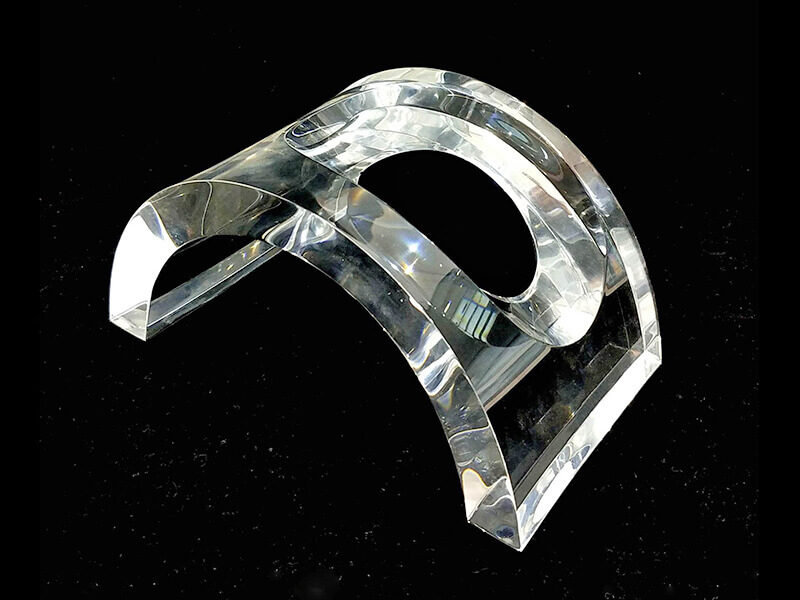

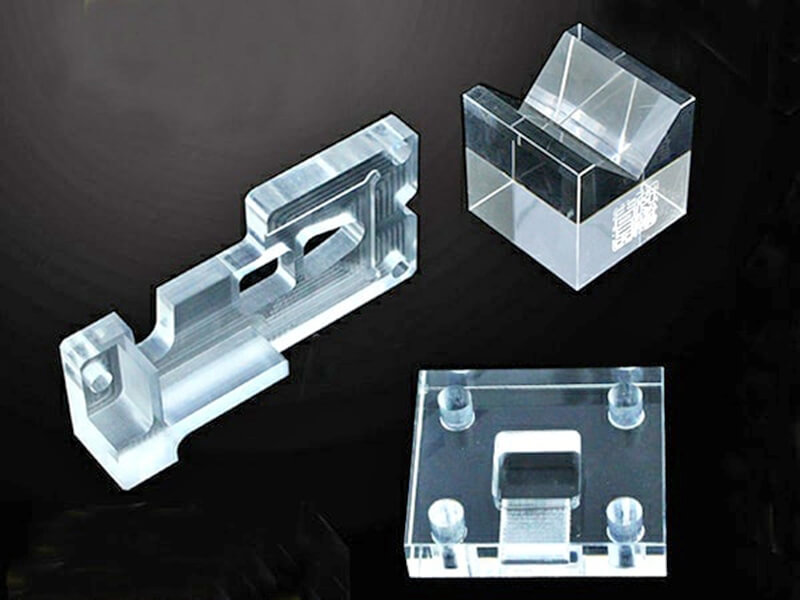

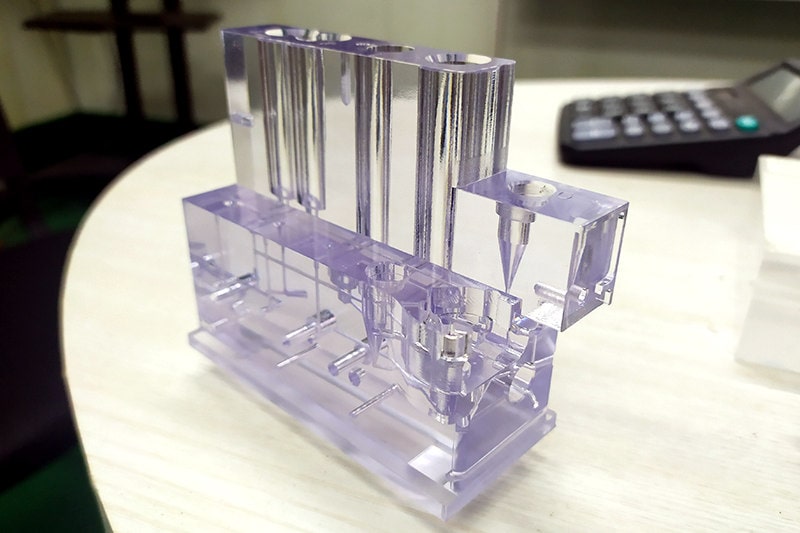

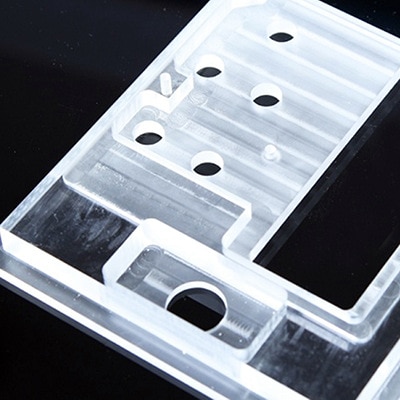

CNC Machining Polycarbonate

UVPLASTIC has Five-Axis precise CNC machines and provides custom polycarbonate parts with a tight tolerance for industry applications, for example, the automation industry, semiconductor, medical industry, electric industry, aircraft industry, etc.